23 July 2020

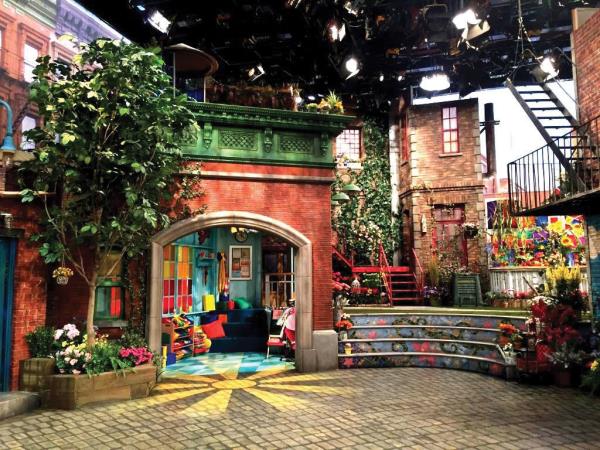

Showman Fabricators designs and creates custom sets and environments, using all kinds of materials and shape-building techniques.

Hanging from the studio ceiling 25 feet up, the servo motors hoist these scenic elements — large “light rings” containing LEDs that shine in multiple colours — on command to specified positions above the studio’s floor. These positions are pre-programmed into programmable logic controllers (PLCs), the brains behind many industrial automation systems. The commands are sent over ethernet, strung up into the ceiling, from the stagehand’s touch-screen operator station at floor level to the motors above.

Using Clearpath’s PC-based setup and configuration software, the servo motors need to be commissioned with such parameters as the weight of scenery element they lift. And that, in turn, requires a one-to-one USB connection – whose cable length limit is 16 feet, or five meters — between PC and servo motor. The Clearpath software is also needed for system monitoring and possible troubleshooting, to ensure the precision of those positions and movements.

Manually plugging each of 20 ceiling-mounted motors into a PC — presumably while standing on a scissor lift — was not going to work. The only practical way that Showman Fabricators could effectively tune servo motors that were mounted on the ceiling, was by simulating that direct USB connection over that same ethernet network.

“This was only the second project we’d used these particular servos for,” says Ryan Poethke, automation and electrical designer at Showman Fabricators

That path led Poethke to a PLC programming discussion forum, where he picked the brains of fellow engineers. He asked forum members to recommend a solution with crash-resistant software (rebooting devices hanging from the ceiling to re-establish connectivity was also a non-starter); easily customized addressability, so that each of 20 devices would have logical names; DIN-rail mounting, and 24V power, requiring no separate power supply.

SEH Technology’s INU-100 USB device server soon rose to the top of the list for several reasons. Importantly, notes Poethke, they were able to confirm lead time for a relatively large quantity — 20 — units. Equally important, test samples are a standard service at SEH, something other vendors were unwilling or unable to provide. Showman couldn’t commit to purchasing 20 device servers with the chance there would be incompatibilities.

Poethke’s automation and electrics department team built a Showman-Fabricators-branded control cabinet, for each of the 20 servo motors.